Indian Spinning Industry is the most modern and efficient in the world. With 47 Million Spindles and 0.75 Mn Open-End Rotors, India has the world’s second largest spinning capacity, commanding a share of the global Cotton Yarn market . It is currently producing over 4700 million kgs of spun yarn of which over 3,400 Mn.Kgs is cotton yarn. Cotton Yarn accounts for nearly 73% of total spun yarn production.

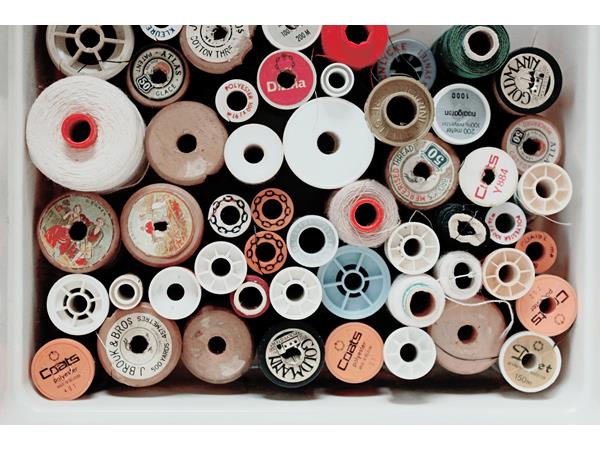

India produces a comprehensive range of yarns for every conceivable end use – non-spun or open-end; combed or carded, basic, compact, mélange or fancy. India’s 1943 spinning mills produce them all for requirements ranging from a fine 200 count to a coarse 2 count.

With more companies modernizing their mills with state-of-the-art technology, Indian cotton yarn markets is set to boost its export potential. The world’s most renowned Indian Cotton Yarns are available as greige, bleached, mercerized, gassed, twisted, dyed or an endless range of fashion yarns like mélange, stretch, blends, high twist and so on to meet the different applications in fashion, clothing, home textiles, hosiery and industrial fabrics. India can meet every customer requirement whether large or small, regular or customized, premium or basic.

Indian yarn spinners have inducted technologies like compact spinning, using the most advanced yarn – processing technology and high-precision process controls tools like electronic cleaners, auto slavers, splicers, two-for-one twisters and auto-coners give Indian mills a competitive advantage.

Today, Indian yarn is widely accepted in International markets as the exporters here regularly meet the needs of importers with unmatched efficiency.

China is the largest importer of yarns from India. Prices of major raw materials like purified terephthalic acid (PTA) and mono-ethylene glycol (MEG) have major influences on yarns markets and prices, besides crude market – which is the fundamental key raw material .

India government has acted on various times to impose anti-dumping duty on polyester staple fibre imports to protect the sector in India. The Directorate General of Anti-dumping and Allied Duties (DGAD), under the commerce ministry provides advice to Government of India

News

Agrawal Polyfil plans forward integration programme at Malav

Laguna Clothing inaugurates garment manufacturing unit in Kanakapura

Sumeet Industries to enhance its capacity of PFY at Surat

Suryalata Spinning Mills plans expansion of its spindle capacity

TT Ltd plans expansion programme

Sri Venkata Umashankar Spintex to set up new unit in Vemavaram

List of Indian Yarn Manufacturers in India

(no title)

A B Cotspin India Ltd

A V Spinners

Aabhas Spinners Pvt Ltd

Aakavi Spinning Mills Pvt Ltd

Aananda Lakshmi Spinning Mills Ltd

Aarti Yarnfab Pvt Ltd

Aastha Spintex Pvt Ltd

Aathivelan Mills